Food and Packaging Capabilities at TPC Packaging Solutions

TPC offers the form, fill, and seal machines necessary for safe and rapid processing. In addition, we have stainless steel variants of all standard packaging machinery, which can endure rigorous sanitation and washdown procedures. We tailor equipment solutions to each client’s needs and constraints, working together to ensure that your ultimate setup maximizes efficiency and regulatory compliance.

TPC’s packing equipment enables the following processes:

- Filling: Precise weigh-filling machines allow you to tightly control the package filling process, ensuring each package receives exactly the right quantity of product.

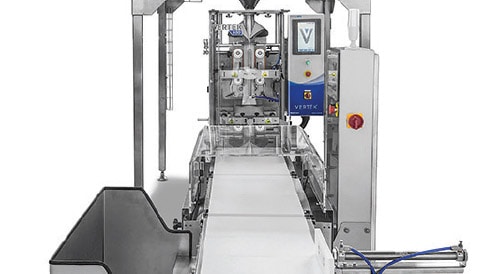

- Vertical Forming, Filling, and Sealing: Our vertical form, fill, and seal equipment combines multiple packaging processes into one efficient step. This equipment creates a film pouch, weighs and fills the pouch with a precise quantity of product, and then seals the top to protect the contents. With these stations, you can rapidly package high volumes of product without sacrificing accuracy.

- Wrapping and Horizontal Flow Wrapping: Ideal for individually packaged food items, our wrapping equipment encases products in airtight film pouches.

- Capping: Automated capping machines rapidly seal bottles and cartons with airtight, hygienic caps.

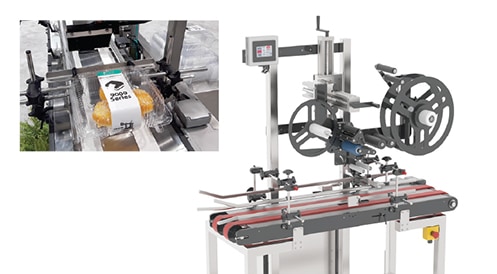

- Labeling: Our automatic self-labeling machines quickly and smoothly apply custom labels to bottles, cans, containers, and boxes of all kinds. These machines speed the process of applying both branding materials and nutritional information to food and beverage products.

- Case Erecting: Case erectors automatically unfold and assemble cardboard cartons and boxes for filling. Tray formers can also quickly produce cardboard trays for packing and shipping.

- Case Sealing: Case sealers offer another means of optimizing your packaging processes, automating case closure to further reduce manual labor. Our machines can handle standard cases of all sizes, including overfilled and underfilled packages, helping you get every shipment out of your facility fast. We also offer tape and glue as sealing options.

- Palletizing: Pick-and-place robotic palletizing equipment makes it easy to efficiently create ready-to-ship pallets of bags, cartons, and containers of any shape. In combination with case erecting and sealing equipment, our pick-and-place palletizing machines help you achieve absolute efficiency in our packaging processes.

- Temperature-Controlled Packaging: Temperature-controlled packing processes ensure that your perishable products are never exposed to excess temperatures. We offer cold resistant packing materials and sealants to keep packages sealed across the entire cold chain. In addition to controlling ambient temperatures and packing products in insulated shippers, we also recommend our temperature indicators, which detect deviations from acceptable temperatures.

- Vacuum Bags and Packing: Vacuum sealing is the best way to ensure that virtually no oxygen can enter your package. The process is ideal for perishable products like meats that could spoil if exposed to any moisture, oxygen, or environmental contaminants. Our shrink vacuum bags adhere tightly to food products to minimize waste and seal in flavor. We offer both bags and packing equipment to facilitate this essential process.

In combination, these machines form a smooth workflow, leveraging automation for maximum efficiency. We can help you assemble a custom packaging system from these options, tailored to your facility’s size, workflow, and product types.

Food & Beverage Packaging Supplies at TPC Packaging Solutions

Our food and beverage packaging supplies are engineered to retain flavor and repel moisture and contaminants. Our food-safe offerings include:

- Carton Sealing Tape: Our sealing tapes use a variety of adhesives to seal all kinds of packing materials, including those exposed to refrigeration (not to be used in direct food contact).

- Label Applicators: We offer equipment and label supplies to help clients apply information to boxes, pallets, and individual products. Our products accommodate labels for branding and marketing, nutrition information, shipment tracking, and tamper evidence, and other applications.

- Packaging Equipment: Automated packaging equipment offers massive reductions in lead times and allows you to place employees where they are most productive. Our team helps clients determine which automation solutions would be most impactful for their facility’s workflow. Options include pick and place machines, stretch and shrink wrap applicators, and case sealers, among others.

- Polybags: Polybags are polyethylene, polypropylene, or blended film bags used to protect products from dirt and moisture. We offer plain, custom-printed, and custom-sealing polybags of all sizes to help clients protect their products.

- Case Sealers and Formers: Our case sealers and formers allow you to quickly and cost-effectively assemble large quantities of crates and trays.

- Bag in Box Systems

- Shrink Wrap: Shrink wrap is a staple of the food and beverage packaging industry, used to assemble multi-packs and display candies. We provide USDA and FDA-approved shrink wrap for food-safe wrapping.

- Stretch Wrap: Stretch wrap seals and stabilizes pallets for shipping, minimizing product damage.

- Pouches: In addition to zippered polybags, we also offer stand-up pouches suitable for snacks and other small food products.

- Pallet Covers/Bags

Food & Beverage Packaging: Applications & Advantages

Specialized food and beverage packaging is essential to preserving a product’s flavor and freshness. These materials also carry additional benefits, such as protecting the food’s color and texture and preventing tampering.

Food and beverage packaging accomplishes these goals by incorporating materials with a low oxygen transmission rate (OTR), which corresponds to a high relative oxygen barrier. Oxygen is responsible for many of the chemical reactions that lead to food spoilage, as well as for oxidative processes that diminish flavor and cause a stale taste. Oxygen is also necessary for many pathogenic bacteria to reproduce, meaning that removing oxygen from a package can prevent harmful bacterial growth. For these reasons, one of the primary goals when designing food and beverage packaging is to minimize the amount of oxygen present.

Materials with a high oxygen barrier, including specialized barrier films and polybags, inhibit the rate at which oxygen can enter the package, slowing spoilage, bacterial growth, and moisture loss. These materials are essential to preserving the quality of packaged foods, especially when handling produce or other products prone to mold.

In addition to limiting oxygen, effective food and beverage packaging also ensures that the enclosed product remains at an appropriate temperature and resists any surrounding humidity. Although proper transport processes are perhaps more influential in determining temperature and moisture exposure, well designed packaging minimizes the impact of any fluctuations, decreasing the amount of food waste in transportation.

Controlling temperature and oxygen transmission ensures that clients receive healthy, flavorful products with their aroma, color, and texture intact.

Applications

Food and beverage packaging is critical to ensure that any edible product remains shelf-stable. While all food and drinks must be packaged in accordance with health regulations, special care is necessary with products that could be damaged during transit, whether due to mechanical or chemical forces. Depending on the food’s shelf life, packaging precautions might include insulation, waterproofing, tamper-evident seals, and vacuum wrapping.

Food & Beverage Packaging From TPC Packaging Solutions

At TPC Packaging, we understand the intricacies of food-safe and cold chain shipping processes. We work closely with clients to develop individualized automation systems that protect products and minimize labor costs, all without interrupting facility operations. We also support clients with food-safe packaging materials ranging from tamper indicators to snack pouches, making us a one-stop-shop for food and beverage packaging solutions.

To learn more about how our equipment and supplies can optimize your shipping procedures, contact our team today.