What Is Packaging Automation Equipment?

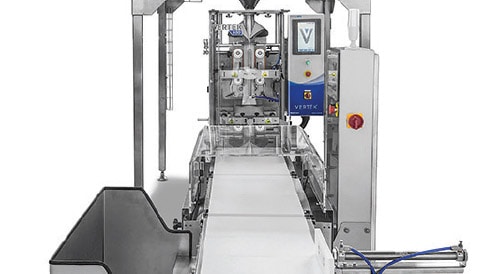

Automated systems can perform complex tasks with little to no human intervention to add higher levels of efficiency. Simple automated packaging machines of individual equipment units can automate single tasks like creating or sealing packaging, whereas more robust packaging equipment solutions can fully automate production, managing the entire process of packaging, arranging, unitizing and preparing large pallets for product transportation and sale.

Using robotics in your equipment is one way of accomplishing increased levels of packaging automation for more complex tasks, complementing your automation machinery through fast, accurate pick and pack procedures. In packaging, robots can identify a needed item for an order, lift it off of a continuous conveyor system and place the item into the tray or case packaging. At TPC, we have various automation and robotic solutions available to efficiently manage your packing operation.

Benefits & Advantages of Packaging Automation

Packaging automation systems are an excellent investment for any industrial facility that wants to increase production speeds while improving worker safety and satisfaction. Some of the key benefits of packaging automation are:

- Accuracy. Automated systems can follow programmed instructions without the risk of human error. They can also carry out accurate counting and evaluations of work tasks.

- Consistency. Packaging automation will ensure that packages have the correct number of components and the right enclosures, and will apply correct sealing methods to the packaging with virtually no variation between packages within a set.

- Efficiency. Automated systems minimize product waste, the risk of errors and costly delays, and can make the most efficient use of space and material resources.

- Employee morale. Automated packaging systems increase job satisfaction, reduce time spent on manual and repetitive tasks and decrease the likelihood of occupational injuries.

- Increased production. Automation packaging systems perform faster than human employees, and they can function around the clock without interruption, boosting productivity.

- Safety. Automated equipment can easily handle sharp or heavy packages and tools, as well as repetitive tasks, to minimize the risk of injury to human employees.

Types of Packaging Equipment

At TPC, we specialize in creating custom automated packaging and robotics solutions so that each of our clients has access to the tools and assemblies they need to succeed. Our catalog includes the following packaging equipment:

Our case erectors can scale your packaging process by quickly and efficiently transforming flat boxes into folded, assembled and sealed corrugated cases and cartons without the need for manual intervention. Our array of automated case erectors will help your business save on production time and costs through reduced labor. To best fit your operation, we offer various versions and sizes of case erectors to handle different capabilities and packaging formats. You also have the option of hotmelt glue or tape for creating a seal on the case or carton base.

Cold Seal Packaging

Cold seal packaging is a versatile technique that utilizes two films: one that safeguards a package’s interior product by providing a barrier, and another that manufacturers reverse-print with a company’s branding information or logo. Our automated systems use simple pressure to efficiently and rapidly seal goods in a protective film wrapping to prepare your packages for shipping or inventory and storage. Cold seal packaging is a versatile option for use with multiple materials, and it is a cost-effective one as well because the boost in productivity that automation provides lowers the cost per packaging unit.

Case Packers

This equipment can quickly pack rigid or flexible packs of goods into corrugated cases, trays, and displays of any size or style through top-loading. Case packers have the capability to layer products for different pack patterns, as needed. Switching from manual to automated processes for case packing services decreases your need for labor costs with reduced worker/machine interaction, and you optimize your production output.

Robots & Cobots

The easiest production processes to automate are those that are repetitive in which a fixed pattern is followed. Industrial robots are ideal for automating tasks such as picking products, transferring parts, and palletizing the products for storage and shipment.. Alternatively, cobots, or collaborative robots, can carry out similar processes while also having the capability to safely work alongside employees outside of a robotic workcell. Whichever option you select for your operation, robots and cobots will improve accuracy, efficiency, production speed, volume, and costs.

Palletizing Robots

Palletizing is a repetitive and tedious task when employees complete it manually. It takes quite a bit of time as well as strenuous physical labor. Automating the palletizing process allows you to allocate your employees to other tasks, all while increasing speed and efficiency in the process. Robots focusing on palletizing tasks have the added benefit of repeatable accuracy, able to stack and load pallets to the ideal filling degree. Automation can help keep your workers happy and injury-free while also reducing your bottom line by letting robotic technology handle the heavy workloads. The optimized productivity and enhanced freight economy will typically make up your equipment investment in less than two years.

Workcells

Robotic workcells can improve quality and speed and lower the cost of production. A cell includes a robot, controller and other equipment to perform its intended applications. With a robotic workcell, you will have a streamlined process from start to finish. There are multiple workcell options available to fit any kind of need. When pre-engineered, workcells will be ready for quick installation, or you can customize and design a cell to your specific requirements. To choose the best workcell for your process, we will need to know the type of application, size specifications and the intended outcome of the system.

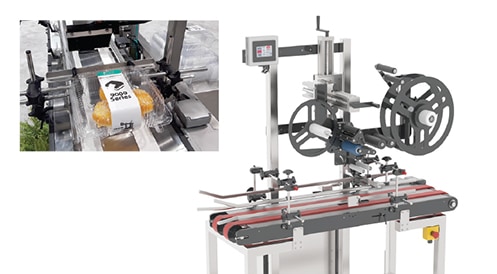

Sealing unique boxes can be challenging with standard equipment. Case sealers, also known as carton sealing machines, can reliably and efficiently close and seal the lids of cartons and packaging after the packing phase of production. TPC is able to work with your unique box to find custom case sealing equipment to offer automation for an otherwise manual process. Tall, short, narrow, large, H-Seals, L-Clips and C-Clips are just some of the unique boxes and sealing options for which we are able to provide solutions.

Tray forming begins when corrugated sheets of cardboard feed from a magazine into the first forming station in the machinery. Next, the automated process spreads a hotmelt, or hot glue, onto the tray flaps so that, when a mold lowers and forms three walls of the tray, the closure flaps will adhere. Finally, at the last forming station, the gathered containers move into the tray and the fourth tray wall closes behind them.

TPC is a proud distributor of Wexxar Bel tray formers. The Wexxar Bel IPAK Series of automatic tray formers can assemble trays in a variety of sizes and configurations, such as regular slotted versions, for retail, agriculture, personal care, pharmaceuticals and more! Styles include open-style trays, trays with lids, display trays and self-locking trays (no glue).

Choose TPC Packaging Solutions for Packaging Automation

TPC has been serving clients in nearly every industrial sector with efficient, automated packaging solutions for over 50 years. As an ISO 9001:2015-certified company, we have a strong commitment to quality and innovation. It is our goal to increase the effectiveness of your processes by offering value-added products and equipment with competitive pricing and just-in-time delivery.

Contact us today to partner with TPC and begin choosing or designing the right automated solution for your needs.