Case Erectors

Case erectors are a type of packaging equipment designed to convert flat blanks into fully erected cartons or boxes. At TPC Packaging Solutions, we deliver a wide range of converting services and packaging equipment solutions, including case erectors. Our case erectors are available in various configurations and can be customized to meet your particular needs and constraints.

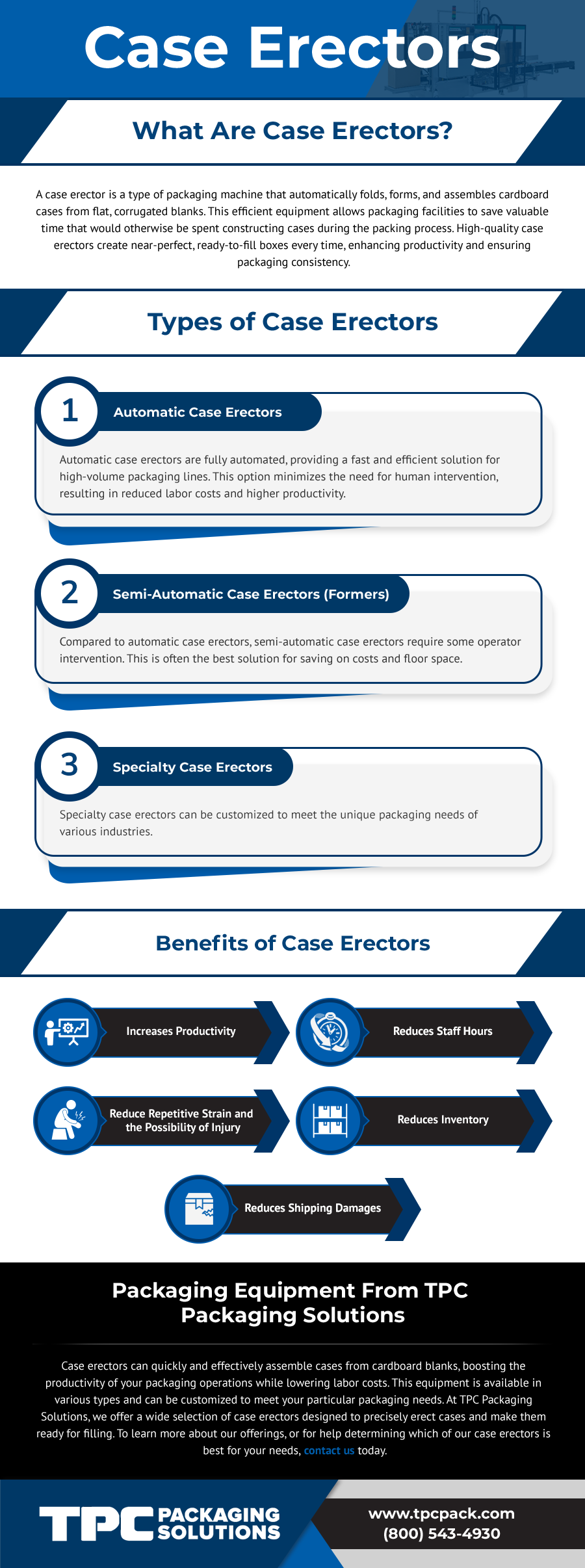

What Are Case Erectors?

A case erector is a type of packaging machine that automatically folds, forms, and assembles cardboard cases from flat, corrugated blanks. This efficient equipment allows packaging facilities to save valuable time that would otherwise be spent constructing cases during the packing process. High-quality case erectors create near-perfect, ready-to-fill boxes every time, enhancing productivity and ensuring packaging consistency. Depending on your particular needs, some case erectors can even assemble recycled or used boxes, resulting in increased savings compared to buying new stock each time.

Types of Case Erectors

There are three main types of case erector machines to choose from:

- Automatic Case Erectors. Automatic case erectors are fully automated, providing a fast and efficient solution for high-volume packaging lines. This option minimizes the need for human intervention, resulting in reduced labor costs and higher productivity.

- Semi-Automatic Case Erectors (Formers). Compared to automatic case erectors, semi-automatic case erectors require some operator intervention. This is often the best solution for saving on costs and floor space.

- Specialty Case Erectors. Specialty case erectors can be customized to meet the unique packaging needs of various industries.

To learn about our specific case erector offerings, view our catalog.

Benefits of Case Erectors

Case erectors provide various benefits to distribution centers and packaging lines. These benefits include:

- Increases productivity. Compared to manual options, automatic and semi-automatic case erectors significantly increase the speed that cardboard blanks can be formed into folded and sealed cases.

- Reduces staff hours. Automatic case erectors can ramp quickly to meet growing demands without requiring additional labor. This reduces the need for overtime and allows employees to focus on more important areas of production.

- Reduce repetitive strain and the possibility of injury. Manually assembling cases is a highly repetitive process that can result in employee strain and other injuries. Employing an automatic or semi-automatic case erector allows facilities to reduce workplace injuries related to repetitive motions.

- Reduces inventory. To be shipment-ready, manufacturers and distributors often have to store numerous assembled boxes, which can take up a lot of space. Case erectors quickly and easily prepare cases as needed, allowing facilities to fulfill last-minute orders and large shipments without the costs associated with storing/transporting pre-erected boxes.

- Reduces shipping damages. Case erectors form cases with high precision, resulting in near-perfect boxes free from damage. Human error can result in cases with poor adhesion and malformed corners that can result in cases opening during shipment and damaging goods.

Packaging Equipment From TPC Packaging Solutions

Case erectors can quickly and effectively assemble cases from cardboard blanks, boosting the productivity of your packaging operations while lowering labor costs. This equipment is available in various types and can be customized to meet your particular packaging needs. At TPC Packaging Solutions, we offer a wide selection of case erectors designed to precisely erect cases and make them ready for filling. To learn more about our offerings, or for help determining which of our case erectors is best for your needs, contact us today.