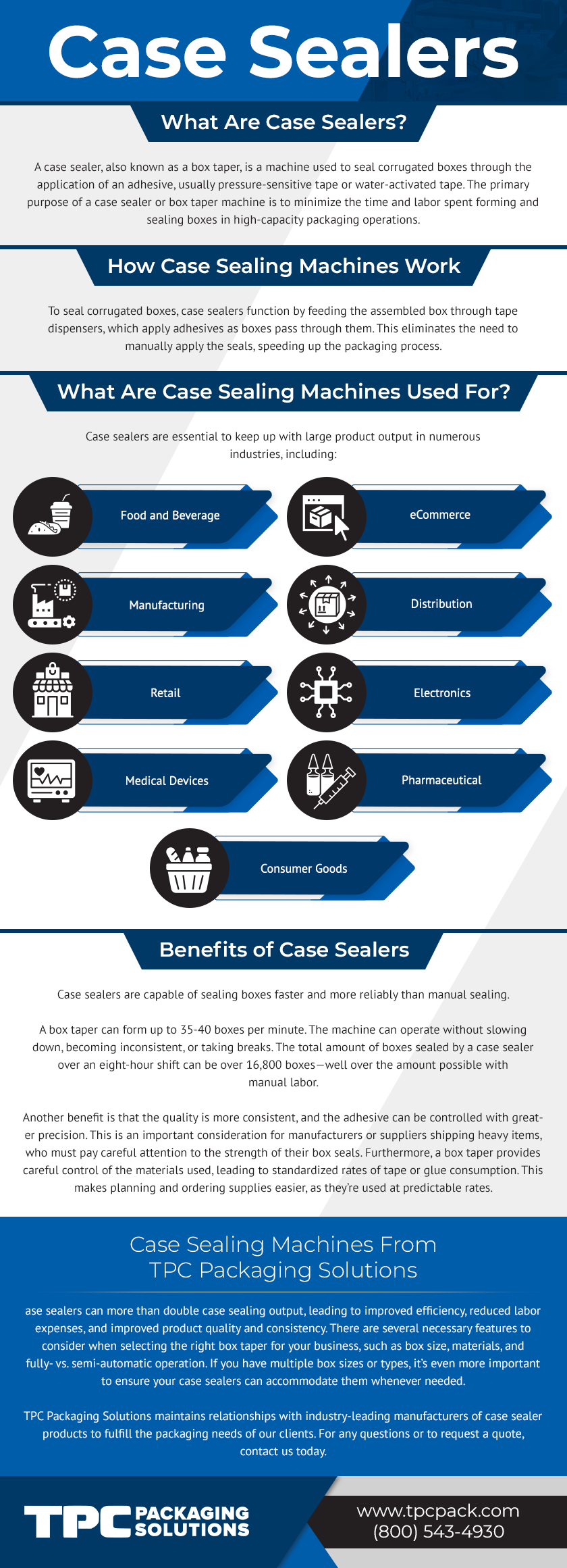

Case Sealers

Browse Tape Machines/Case Sealers

What Are Case Sealers?

A case sealer, also known as a box taper, is a machine used to seal corrugated boxes through the application of an adhesive, usually pressure-sensitive tape or water-activated tape. The primary purpose of a case sealer or box taper machine is to minimize the time and labor spent forming and sealing boxes in high-capacity packaging operations.

How Case Sealing Machines Work

To seal corrugated boxes, case sealers function by feeding the assembled box through tape dispensers, which apply adhesives as boxes pass through them. This eliminates the need to manually apply the seals, speeding up the packaging process.

What Are Case Sealing Machines Used For?

Case sealing machines are useful in any industry that requires folding and sealing high volumes of corrugated boxes from flat boxes. Depending on the type of equipment, case sealers can be fully or partially automated.

The case sealer or box taper can be either automatic or semi-automatic, and its function is to seal the filled box with either glue or tape. When married with a case former, a case sealer provides almost fully automated forming and sealing of corrugated boxes—from flat, pre-formed boxes to fully sealed, ready-to-ship packages.

Case sealers are essential to keep up with large product output in numerous industries, including:

- Food and beverage

- eCommerce

- Manufacturing

- Distribution

- Retail

- Electronics

- Medical devices

- Pharmaceutical

- Consumer goods

Benefits of Case Sealers

Case sealers are capable of sealing boxes faster and more reliably than manual sealing. By hand, a worker can assemble and seal an average of three boxes per minute, which amounts to 1,260 boxes in a standard eight-hour work shift with breaks. Although this rate is high over the long term, it requires incredibly repetitive labor. Quality may eventually suffer, and this puts products at risk, especially in transit after leaving the facility.

In that same eight-hour period, a box taper can form up to 35-40 boxes per minute. The machine can operate without slowing down, becoming inconsistent, or taking breaks. The total amount of boxes sealed by a case sealer over an eight-hour shift can be over 16,800 boxes—well over the amount possible with manual labor.

Another benefit is that the quality is more consistent, and the adhesive can be controlled with greater precision. This is an important consideration for manufacturers or suppliers shipping heavy items, who must pay careful attention to the strength of their box seals. Furthermore, a box taper provides careful control of the materials used, leading to standardized rates of tape or glue consumption. This makes planning and ordering supplies easier, as they’re used at predictable rates.

Case Sealing Machines From TPC Packaging Solutions

Case sealers can more than double case sealing output, leading to improved efficiency, reduced labor expenses, and improved product quality and consistency. There are several necessary features to consider when selecting the right box taper for your business, such as box size, materials, and fully- vs. semi-automatic operation. If you have multiple box sizes or types, it’s even more important to ensure your case sealers can accommodate them whenever needed.

TPC Packaging Solutions maintains relationships with industry-leading manufacturers of case sealer products to fulfill the packaging needs of our clients. For any questions or to request a quote, contact us today.

We offer quality products from:

If you need case sealers or would like to learn how the right case sealer can improve your facility’s shipping process, contact us at 800.543.4930. One of our TPC representatives will be happy to help you optimize your company’s shipping process.

Tape Machines Gallery

Click on the images below to enlarge.