Cold Chain/Temperature Controlled Packaging

Cold chain packaging, also known as temperature-controlled packaging, refers to packaging and distribution methods specifically engineered to keep products at a constant temperature from production through final distribution. While initially established to keep temperature-sensitive goods refrigerated or frozen in transit, temperature-controlled packaging solutions have expanded to encompass packaging that protects room temperature products from extreme external temperatures.

At TPC, we provide cold chain packaging solutions for the strict demands of shipping food, medicine and temperature-sensitive materials. We offer a wide range of products for temperature-controlled shipping, including gel packs/refrigerants to insulated shippers and pouches to EPS molded coolers and insulated pallet shippers. We also have cold temperature packing tapes and stretch film, as well as temperature indicators.

Whether a product is sitting in a warehouse or being shipped across the country or across the globe, if temperature matters, that product is part of the cold chain. A decade ago, the term “cold chain” referred only to products that needed to be cooled. Now it also includes products that must be kept at room temperature and those that must be protected from cold and heat. As more and more of these products enter the supply chain, the term “cold chain” has morphed to “controlled temperature.”

- Thermal/Insulated Shippers

- Gel Packs

- Cold Temperature Tapes

- Cold Temperature Stretch Film

- Temperature Indicators & Recorders

- Reflective Bubble Mailers

- Insulated Pallet Liners

- Insulated Pallet Covers

- Curbside Recyclable Shippers

- Sustainable Shippers, Cotton and Plant Based

- EPS Molded Coolers

We offer quality products from:

- Polymer Ice Packs

- Semi-Rigid Foam Bricks

- No Sweat Gel Packs

- Drain Safe Packs

We offer quality products from:

Machine film for extreme cold or dusty environments where film tails create problems for automated handling warehouses. Guaranteed wipe down of the film tail. Will run on any piece of equipment. High clarity = no issues with bar code scanner. Excellent load containment.

High stretch level with great puncture resistance.

We offer quality products from:

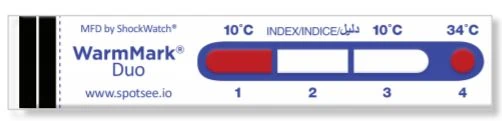

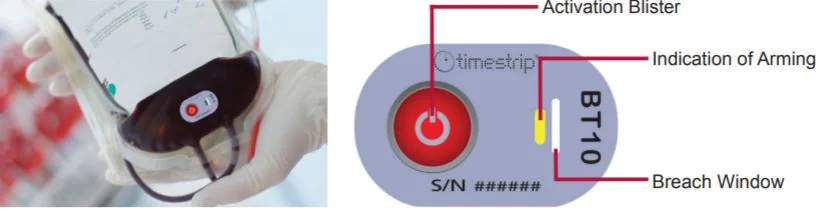

Temperature indicators and recorders introduce accountability measures into the shipping and handling stages of the temperature sensitive cold chain. In the event that a temperature excursion occurs, indicators and recorders give you the data needed to improve the integrity of the cold chain.

Temperature monitoring and measuring devices play a vital role in identifying temperature-related events, and empower you to take meaningful action to reduce the likelihood of product damage.

ColdMark Temperature Indicators

WarmMark Temperature Indicators

WarmMark Duo Indicators

FCP Descending Temperature Indicators

Blood Temp Indicators

Cold Chain Complete Indicators

Log-IC Temperature Recorders

TempU Temperature Recorders

SpotBot Cellular

BLE Temperature Recorders

We offer quality products from:

Cold Chain/Temperature-Controlled Packaging Applications

Temperature-controlled packaging ensures that products maintain a desired temperature consistent with relevant safety regulations and quality standards. Cold chain packaging is used in a wide range of industries, including:

Pharmaceutical

Many over-the-counter and prescription medications require temperature-controlled conditions to maintain optimal effectiveness. Many vaccines must be kept frozen or refrigerated within very specific temperature ranges to remain fully effective.

Food and Beverage

Fresh produce, dairy products, eggs, and frozen food are just a few examples of products that must be packaged and shipped in temperature-controlled packaging. Cold chain packaging solutions keep produce fresh, maintain frozen food at appropriate temperatures, and prevent sensitive products like candies and confections from melting in transit.

Chemicals

To prevent dangerous exothermic reactions, chemicals are often transported in refrigerated or temperature-controlled packaging. This prevents exposure to heat that may cause sparks, flames, or explosions.

Cosmetics and Personal Care

Many cosmetics and personal care products such as makeup, soap, and lotions must be contained in temperature-controlled packages. Exposure to heat or freezing temperatures outside the product’s allowable range can result in product separation, breached seals, contamination, spills, and poor product quality.

Advantages of Cold Chain and Temperature-Controlled Packaging

Cold chain packaging offers a variety of benefits, including:

Product Quality

Using top-quality temperature-controlled packaging maintains consistent product quality from the manufacturing facility through distribution. This ensures greater customer satisfaction and reduces the potential for product loss, thereby increasing your overall profitability.

Consumer Satisfaction

With insulated packaging, you ensure that your customers receive high-quality products with a high degree of consistency and reliability. In today’s digital age, this translates to return customers, good reviews, and greater customer satisfaction with your brand. What’s more, you can pass your savings on to the customer to make your brand more competitive in the marketplace.

Distribution Standards

As customers become more conscious of product sourcing, there is an increased level of regulation and accountability for companies in every industry. By using temperature-controlled and cold chain packaging, you can stay ahead of the game. Keep your products at optimal temperatures to avoid product recalls and stay ahead of increasingly stringent distribution standards around the world.

Cold Chain Packaging Capabilities at TPC Packaging Solutions

TPC is committed to meeting the stringent standards for food, pharmaceutical, and other temperature-sensitive product shipping and distribution. We know that each product will have different temperature and handling requirements, and we understand that it is critical for temperature-controlled products to be kept within their required temperature ranges at all times. We are conscientious about every aspect of packaging to help our customers meet and exceed even the most rigorous industry standards for temperature protection.

Our selection of temperature-controlled packaging solutions includes:

- Thermal Insulated Shippers

- Reflective Bubble Mailers

- Insulated Pallet Liners and Covers

- Curbside Recyclable Shippers

- Cotton and Plant Based Sustainable Shippers

- EPS Molded Coolers

- Insulated Pouches

- Standard and No-Sweat Gel Packs

- Polymer Ice Packs

- Semi-Rigid Foam Bricks

- Cold Temperature Tapes to -40°F

- Cold Temperature Stretch Film

- Temperature Indicators and Recorders

- Freezer Labels

Choose Cold Chain & Temperature-Controlled Packaging at TPC Packaging Solutions

At TPC Packaging Solutions, we are dedicated to helping our customers find the perfect thermal-control packaging solutions to meet their requirements. We understand that every product has different packaging specifications. With more than 50 years of experience in the packaging industry, the experts at TPC are uniquely skilled at creating quality cold chain packaging solutions for everything from food and produce to pharmaceuticals and temperature-sensitive chemicals. Whether you need to ship frozen seafood or critical vaccines, TPC can help.

Contact us today to see how our packaging can protect your temperature-sensitive goods.

Download Our Free eBook

This eBook provides an overview of cold chain and temperature-controlled packaging solutions, how they work, the various types available, and the many industries in which they are implemented.

Download our free guide!